Predictive maintenance in the aviation industry represents a significant departure from traditional approaches. It relies on data analytics, machine learning (ML) algorithms, and real-time monitoring to predict potential failures in aircraft components before they occur. This proactive strategy contrasts sharply with the reactive nature of scheduled maintenance or component replacements based on predetermined intervals. With the relentless pressures of minimizing downtime, ensuring safety compliance, and optimizing operational efficiency, airlines are increasingly turning to innovative solutions like real-time intelligence to stay ahead of the curve.

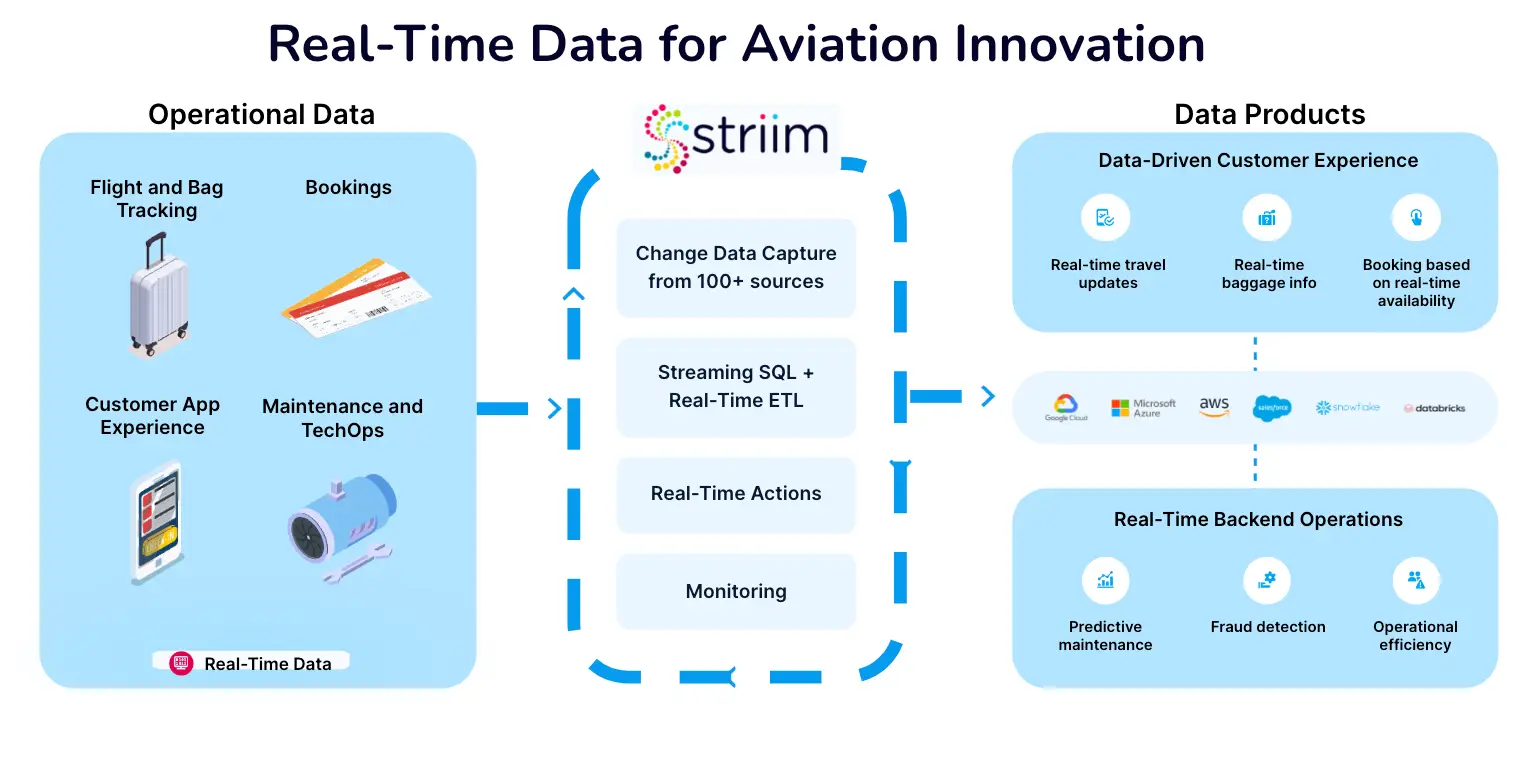

Data Integration and Management: The efficacy of predictive maintenance hinges on the seamless integration and management of heterogeneous data sources. Effective integration ensures that predictive algorithms receive comprehensive datasets for accurate analysis, minimizing the risk of unreliable results.

Data Quality and Consistency: The success of predictive maintenance initiatives heavily relies on the fidelity and uniformity of data acquired from diverse sensors and systems. Inconsistencies or inaccuracies in data could introduce noise, compromising the reliability of predictive models and maintenance schedules.

Aging Fleets: Many aircraft in service today are aging, requiring more frequent maintenance interventions. Predictive maintenance can extend the service life of aging aircraft by identifying potential issues early on, thereby minimizing the need for costly repairs and ensuring continued operational reliability.

Complexity of Modern Aircraft Systems: Modern aircraft systems are highly complex, comprising numerous interconnected components and subsystems. Predictive maintenance algorithms must account for these complexities to accurately predict failures and plan maintenance activities.

Regulatory Compliance: Compliance with aviation regulations is paramount for ensuring safety and reliability. Predictive maintenance solutions must adhere to regulatory standards and obtain necessary approvals, which can be challenging due to the stringent requirements of the aviation industry.

Cost and Resource Constraints: Implementing predictive maintenance systems requires significant investments in technology, infrastructure, and skilled personnel. Budget constraints and resource limitations may hinder the adoption and implementation of predictive maintenance technologies in the aviation industry.

Intelligent Predictive Maintenance: Elevating Aircraft Maintenance Standards

Intelligent predictive maintenance relies on real-time ML-driven data analysis to monitor aircraft components and systems. Through continuous monitoring and analysis, it detects subtle indicators of degradation or impending failures, providing airlines with actionable insights to schedule maintenance preemptively. By addressing potential issues before they escalate, intelligent predictive maintenance not only helps airlines avoid costly downtime but also enhances overall operational reliability, ensuring smoother flight operations and greater passenger satisfaction.

Let’s explore the business benefits of intelligent predictive maintenance:

Real-Time Maintenance Inventions for Uninterrupted Operations

Predictive maintenance minimizes unexpected breakdowns by identifying potential issues early, ensuring continuous service delivery and enhancing customer satisfaction. It allows airlines to address maintenance needs before they escalate into critical failures, reducing the likelihood of disruptions to flight schedules and maintaining operational reliability. By staying ahead of maintenance requirements, airlines can instill confidence in passengers, build trust in their services, and uphold their reputation for reliability.

Driving Cost Efficiencies with Proactive Strategies

Addressing maintenance needs proactively leads to significant cost savings over time, allowing airlines to allocate resources more efficiently. By identifying and addressing issues before they result in costly repairs or replacements, airlines can optimize their maintenance budgets, streamline operational expenses, and improve overall financial performance. Proactive maintenance not only reduces direct maintenance costs but also minimizes the indirect costs associated with downtime, flight cancellations, and passenger compensation.

Early Detection Systems to Safeguard Reliability

Early detection of component issues ensures continued operational reliability, mitigating the risk of costly disruptions and upholding service quality standards. By leveraging real-time data analytics and predictive algorithms, airlines can detect abnormalities or deviations in component performance, allowing for timely intervention and preventive measures. Early detection also enables airlines to implement corrective actions proactively, minimizing the impact on flight operations and ensuring uninterrupted service delivery to passengers.

Maximizing Asset Utilization with Optimized Maintenance Scheduling

Optimizing maintenance schedules based on real-time data insights extends the lifespan of aircraft assets and reduces maintenance costs. By analyzing usage patterns, component health, and operational demands, airlines can develop tailored maintenance schedules that maximize the efficiency of maintenance activities while minimizing downtime. Efficient scheduling ensures that maintenance tasks are performed at optimal times, reducing the likelihood of service disruptions and optimizing the utilization of aircraft assets.

Proactive Maintenance Practices for Operational Continuity

Proactive maintenance fosters operational continuity, ensuring smoother flight operations and enhancing passenger experiences. By proactively addressing maintenance needs and minimizing the occurrence of unplanned events, airlines can maintain a consistent level of service reliability and operational fluidity. Proactive maintenance not only enhances passenger satisfaction but also strengthens brand reputation and loyalty in a competitive market environment.

Real-Time Data and Aviation Success in the Real World

Striim customer, American Airlines, is on a mission to care for people on their life journey. Serving over 5,800 flights a day to over 350 plus destinations across 60-plus countries requires massive amounts of data streaming in real time to support flight operations.

TechOps team members use their skills and expertise to ensure planes, team members, and customers depart and arrive safely and reliably every time on every flight. You may see them at your local airports wearing vests and using iPads to work with ground crew. They track aircraft telemetry across the globe, deploy crews for spot maintenance, and route aircraft to the world’s largest maintenance facility in Tulsa, Oklahoma.

Striim’s Real-Time Intelligence for Predictive Aircraft Maintenance

Leveraging real-time data and ML-driven data analytics, intelligent predictive maintenance anticipates potential failures in aircraft components, a proactive shift from scheduled maintenance practices. Despite hurdles like data integration, aging fleets, system complexities, regulatory compliance, and resource constraints, predictive maintenance promises uninterrupted operations, cost efficiencies, reliability, and optimized asset utilization. Through intelligent predictive maintenance, airlines can navigate modern aviation demands, ensuring smoother operations and heightened customer satisfaction. This shift signifies a new era in aircraft maintenance, where foresight and efficiency redefine industry standards, enhancing reliability and performance across the board.

Ready to experience the future of aircraft maintenance firsthand? Try a free trial for free now!